- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

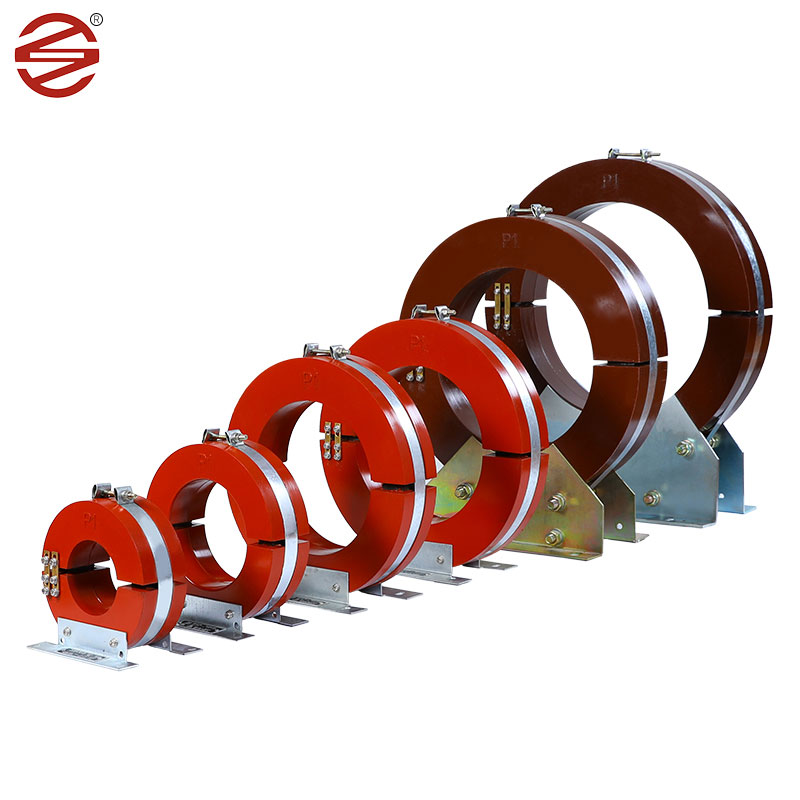

Dry Type transformer

You are welcomed to come to our factory to buy the latest selling, low price, and high-quality Dry Type transformer, Dahu Electric looks forward to cooperating with you.

Send Inquiry

Dry Type transformer Details

Dry-type transformers manufacture by DAHU ELECTRIC are widely used in various applications due to their excellent insulation properties, high efficiency, and environmental friendliness. Here are some of the common application scenarios for resin-insulated dry-type transformers:

Commercial buildings: These transformers are commonly used in commercial buildings, such as office buildings, shopping malls, and hotels, to provide reliable and efficient power distribution.

Industrial facilities: Dry-type transformers are also widely used in industrial facilities, such as factories and warehouses, to power heavy machinery and equipment.

Renewable energy systems: These transformers are an essential component of renewable energy systems, such as wind and solar power plants, where they help to convert and distribute the electrical energy generated by these systems.

Data centers: Dry-type transformers are commonly used in data centers to provide reliable and efficient power distribution to the servers and other equipment.

Hospitals: These transformers are also used in hospitals to power critical medical equipment and ensure uninterrupted power supply.

Marine and offshore applications: Dry-type transformers are suitable for use in marine and offshore applications, where they can withstand harsh environmental conditions and provide reliable power distribution.

Overall, dry-type transformers are versatile and can be used in various applications where reliable and efficient power distribution is required. Their environmental friendliness and low maintenance requirements make them an attractive option for many industries.

Product Introduction

Insulation Material:

The dry type transformer is insulated with high-quality epoxy resin, which provides excellent electrical insulation and thermal stability. The resin insulation ensures the safety and reliability of the transformer, even in harsh operating conditions.

Core Material:

The core of the dry type transformer is made of high-grade, low-loss silicon steel laminations. These laminations are carefully stacked to minimize core losses and improve the overall efficiency of the transformer.

Windings:

The windings are made of high-quality copper or aluminum conductors, depending on the specific requirements of the application. The windings are carefully designed and wound to ensure optimal performance and minimal losses.

Enclosure:

The dry type transformer is housed in a robust and corrosion-resistant enclosure made of high-quality steel. The enclosure provides protection against environmental factors such as dust, moisture, and mechanical stress.

Cooling System:

Dry type transformers are designed with an efficient cooling system to dissipate heat generated during operation. The cooling system may include natural convection, forced air, or a combination of both, depending on the transformer rating and application.

Voltage and Power Ratings:

The dry type transformers are available in various voltage and power ratings to meet different application requirements. The voltage ratings typically range from 1 kV to 36 kV, and the power ratings range from a few kVA to several MVA.

Noise Level:

Dry type transformers are designed to operate with low noise levels, making them suitable for installation in noise-sensitive areas such as residential neighborhoods, hospitals, and schools.

Environmental Friendliness:

These transformers are environmentally friendly as they do not contain any oil or hazardous substances. They are free from the risk of oil leakage, making them safe for both the environment and personnel.

Conclusion:

Dry type transformers offer numerous advantages, including excellent insulation properties, high efficiency, and environmental friendliness. With their robust construction and reliable performance, these transformers are suitable for a wide range of applications in industries such as power generation, distribution, and industrial processes.

Technical data

The transformers shall fulfil the following:

| Nr | Description | Requirement |

| 1 | Dry-type transformer type | Cast Resin (Cast Coil) |

| 2 | Site altitude | <1000m |

| 3 | Operation | Continuous |

| 4 | Installation | Indoors |

| 5 | Ambient temperature (max /daily / annual average)[℃] | 40/30/20 |

| 6 | Tier type (EU 548/2014) | 2 |

| 7 | Rated power | 2000 kVA |

| 8 | Cooling | AN |

| 9 | Rated frequency | 50 HZ |

| 10 | Nominal primary voltage | 11 kV |

| 11 | Nominal secondary voltage | 0.4kV |

| 12 | Insulation level HV (Um/AC /LI) | 12 KV/28 kV/75 kV |

| 13 | Insulation level LV (Um/ AC) | 1.1kV/3kV |

| 14 | Off-load tapping (HV) | ±2x2.5% |

| 15 | Vector group | Dyn 11 |

| 16 | Insulation class (HV /LV) | F/F |

| 17 | HV terminal (lower terminals) | Direct cable |

| 18 | LV terminals |

Top entry,flex

|

| 19 | Climatic classification | C2 |

| 20 | Environmental classification | E2 |

| 21 | Fire behaviour classification | F1 |

| 22 | Impedance voltage (Uk) [%] | 6% |

| 23 | No load losses (Po)[W] | 3600 |

| 24 | Load losses at 75℃ (Pk) [M] | 18000 |

| 25 | Load losses at 120℃ (Px) [W] | 18000 |

| 26 | Maximum acoustic power Lw(A) | 70 dB |

| 27 | Ground acceleration level withstand capability (horiz./vert.) [g] | ≥0.2/≥0.2 |

| 28 | Length [mm] | 1750 |

| 29 | Width [mm] | 1250 |

| 30 | Height[mm] | 2100 |

| 31 | Total weight [kg] | 3700 |

| 32 | Transformer centre distance of wheels [mm] | 1070 |

| 33 | Ingress Protection (IP) | IP00 |

1.8 Fitting and Accessories

Each transformer shall be provided with:

| Nr | Requirement | |

| 34 | Applicable fasteners | 1 set |

| 35 | Earthing balls on HV terminals (upper terminals) | 1 set |

| 36 | Grounding terminals near the bottom | 2 |

| 37 | Finishing of transformer | Standard |

| 38 | PTC temperature sensors located inside the LV windings | 3 sets |

| 38.1 | Trip signal activates at: | 150 |

| 38.2 | Alarm signal activates at | 120 |

| 38.3 | Fan control activates at | 80 |

| 39 | PT100 temperature sensor fixed on outside of transformer | 1 |

| 40 | Terminal box mounted on trans former | 1 |

| 41 | Thermal protection unit (see section 09) | 1 |

| 42 | Earthquake fastenings | 1 set |

| 43 | Rating plate mounted on transformer | 1 |

| 44 | Extra rating plate (loose delivery) | 1 |

| 45 | Lifting eyes and pulling holes | Standard |

| 46 | Housing | No |