- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

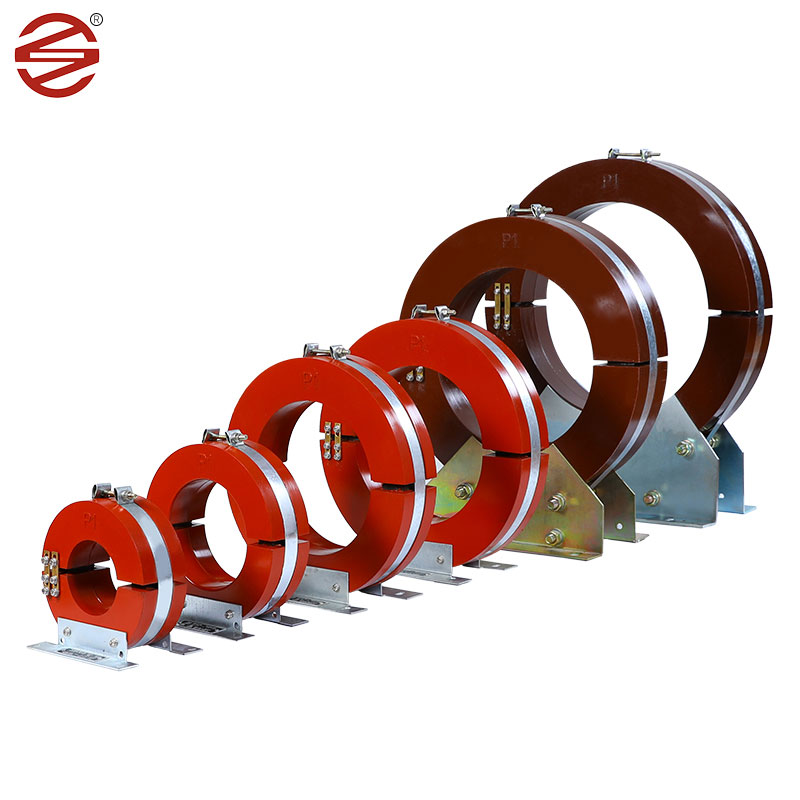

12kv Current Transformer

The 12kV current transformer made by DAHU ELECTRIC is an indispensable component within indoor switch cabinets, serving as the backbone for current measurement, electrical energy monitoring, and protective relays across both single-phase and three-phase AC systems. Its robust design and precise functionality make it an essential element in ensuring the safety and efficiency of electrical operations.

Send Inquiry

Cold-Rolled Silicon Steel Sheets: 12kV current transformers often employ cold-rolled silicon steel sheets for their cores due to their excellent magnetic properties. These materials, being cold-rolled, exhibit high permeability and low core loss, making them ideal for efficient energy transfer. Compared to other options, they have lower hysteresis loops and magnetization losses, resulting in reduced energy waste and lower power consumption. Consequently, systems utilizing current transformers with these materials can cut operating costs and prolong equipment lifespan. In summary, cold-rolled silicon steel sheets are crucial in power systems, ensuring reliable energy transmission and accurate power measurement.

Epoxy resin: Epoxy resin has excellent dielectric properties and mechanical strength, is the first choice of 12kV current transformer insulation material. Epoxy castings provide reliable insulation that protects internal components from electrical breakdown and environmental factors..

Copper : Copper conductors are typically used for windings in 12kV current transformers. These materials offer high electrical conductivity and mechanical durability, enabling efficient transmission of current signals while withstanding operational stresses.

Material (Epoxy Resin ): Enclosures for 12kV current transformers are commonly crafted from epoxy resin, offering a host of benefits crucial for ensuring the safety and efficiency of electrical circuits. Epoxy resin's standout insulation properties serve as a formidable barrier against unwanted current or voltage crossovers, maintaining circuit integrity and safeguarding against electrical hazards.

Notably, its exceptional temperature resistance enables seamless operation even in high-temperature environments, ensuring reliability under demanding conditions. Additionally, its robust corrosion resistance shields the transformer from the damaging effects of various chemical substances, thereby extending its operational lifespan.

Moreover, the superior sealing capabilities of epoxy resin translate into excellent waterproof and moisture-proof performance, rendering the transformer suitable for deployment in humid environments without compromising functionality.

Compared to traditional oil-immersed transformers, epoxy transformers boast a lighter weight, simplifying installation and maintenance procedures. This characteristic not only enhances convenience but also contributes to overall system agility and adaptability.

In essence, the utilization of epoxy resin in transformer enclosures represents a strategic choice, combining advanced insulation properties, resilience in harsh conditions, and ease of handling to ensure optimal performance and longevity in electrical systems.

Product Parameter

| 1. | Application | Metering |

| 2 | Installation | Indoor |

| 3. | Construction | Dry type Epoxy Resin Cast |

| 4 | Insulation | Cast Resin |

| 5. | Number of Phase | Single |

| 6. | Rated Frequency | 50 Hz |

| 7. | System Primary Rated Voltage | 11 kV Phase to Phase |

| 8. | Maximum System Voltage | 12 kV Phase to Phase |

| 9. | System Earthing | Effectively earthed |

| 10. | Basic Insulation Level (1.2/50 μ sec. | 75 KV |

| 11. |

Power Frequency Withstand Voltage (1 min.50 Hz) |

28 KV |

|

12. 13. |

Ratio: 11kV Feeder Primary |

10-20/5A Single Winding |

| 14. | Secondary | Single Winding |

| 15. | Accuracy Class | 0.2/0.25 for Measurement |

| 16. |

Burden a)for Measurement |

7.5-10 VA |

| 17. | Short Time Current Rating | Minimum 10 kA for 1 Sec |

| 18. | Extended Curent Rating | 120%of Rated Current |

| 19. | Over Current Rating | <10A |

| 20. | Creepage Distance | 25 mm/KV(minimum |

| 21. | Standard |

Design,Manufacture,Testing,Installation and Performance shall be in accordance to the latest editions of IBC 61869-1 &IEC 61869-2 |